Oil & Energy

Local Content Implementation Attracts $500m FDI

The Nigerian Content implementation has attracted foreign direct investments into the country worth over $500 million in the manufacturing of equipment components for the oil and gas industry, the Minister of Petroleum, Mrs Diezani Alison-Madueke has said.

Represented by the Permanent Secretary, Ministry of Petroleum Resources, Ambassador Abdulkadir Musa at the opening ceremony of the Practical Nigerian Content in Yenagoa, Bayelsa State, recently, the Petroleum Minister said the equipment component manufacturing initiative was an effective way to drive industrialisation of the economy as it has already created over 1,000 skilled jobs.

The equipment components manufacturing initiative mandates original equipment manufacturers to partner with their representatives to set up facilities to manufactureor assemble equipment components in Nigeria.

Alison-Madueke explained that the initiative will also ensure the retention of spend within the economy on critical industry equipment such as valves, pumps, electrical and instrumentation products.

She expressed optimism that the initiative will ensure that about 30 original equipment manufacturers would have been fully set up in Nigeria in the next five years describing the Nigerian Content Act as the most important development in the nation’s oil and gas industry.

Noting that the impact of the Act was being felt in several sectors of the economy, the minister said, “Nigerians now own land, swamp, jack up rigs. More Nigerians are acquiring anchor handling tugs, dynamic positioning platform vessels, line handling tugs and other larger vessels otherwise called category two vessels.”

She enjoined the local content board to lead the industry to establish vessel and rig maintenance facilities so that the nation’s economy would get the maximum benefits from asset ownership.

On moves by the board in respect of training and employment, she said: “In the last two years, over 500 Nigerians have been provide d with training and employment opportunities under the project based training scheme of Nigerian Content Development and Monitoring Board (NCDMB).

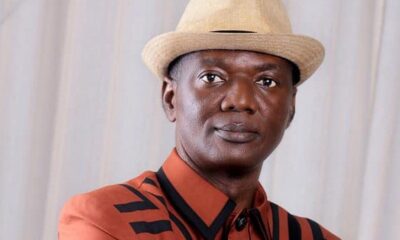

Also speaking the Group Managing Director of Nigerian National Petroleum Corporation (NNPC), Andrew Yakubu, pledged to partner with NCDMB in the industry to ensure that the federal government’s 70 per cent target is attained especially in the deep offshore operation said the participation of Nigerians especially in the upstream sector has increased from a merger 10 per cent to more than 30 per cent since the enactment of the Act.

Citing the USAN Deep Offshore field development as one significant milestone in that respect, Yakubu said: “These percentages are even higher and in some cases have attained 100 per cent. The Utrorogu Gas Plant Expansion Project is an example.”

Other projects with high local content value according to the NNPC boss include the OB3 pipeline project, Escravos Lagos Pipeline Phase 2 and the Aba Depot and Okirika Jetty Rehabilitation project.

He also pointed out that the windows of opportunities to grow the Nigerian Content exist in the upstream, midstream and downstream sectors of the oil and gas value chain.

Oil & Energy

FG Explains Sulphur Content Review In Diesel Production

The Federal Government has offered explanation with regard to recent changes to fuel sulphur content standards for diesel.

The Government said the change was part of a regional harmonisation effort, not a relaxation of regulations for local refineries.

The Chief Executive, Nigerian Midstream and Downstream Petroleum Regulatory Authority (NMDPRA), Farouk Ahmed, told newsmen that the move was only adhering to a 2020 decision by the Economic Community of West African States (ECOWAS) which mandated a gradual shift to cleaner fuels across the region.

Ahmed said the new limits comply with the decision by ECOWAS that mandated stricter fuel specifications, with enforcement starting in January 2021 for non-ECOWAS imports and January 2025 for ECOWAS refineries.

“We are merely implementing the ECOWAS decision adopted in 2020. So, a local refinery with a 650 ppm sulphur in its product is permissible and safe under the ECOWAS rule until January next year where a uniform standard would apply to both the locally refined and imported products outside West Africa”, Ahmed said.

He said importers were notified of the progressive reduction in allowable sulphur content, reaching 200 ppm this month from 300 ppm in February, well before the giant Dangote refinery began supplying diesel.

Recall that an S&P Global report, last week, noted a significant shift in the West African fuel market after Nigeria altered its maximum diesel sulphur content from 200 parts per million (ppm) to around 650 ppm, sparking concerns it might be lowering its standards to accommodate domestically produced diesel which exceeds the 200 ppm cap.

High sulphur content in fuels can damage engines and contribute to air pollution. Nevertheless, the ECOWAS rule currently allows locally produced fuel to have a higher sulphur content until January 2025.

At that point, a uniform standard of below 5 ppm will apply to both domestic refining and imports from outside West Africa.

Importers were previously permitted to bring in diesel with a sulphur content between 1,500 ppm and 3,000 ppm.

It would be noted that the shift to cleaner fuels aligns with global environmental efforts and ensures a level playing field for regional refiners.

Oil & Energy

PHED Implements April 2024 Supplementary Order To MYTO

The Port Harcourt Electricity Distribution (PHED) plc says it has commenced implementation of the April 2024 Supplementary Order to the MYTO in its franchise area while assuring customers of improved service delivery.

The Supplementary order, which took effect on April 3, 2024, emphasizes provisions of the MYTO applicable to customers on the Band A segment taking into consideration other favorable obligations by the service provider to Band A customers.

The Head, Corporate Communications of the company, Olubukola Ilvebare, revealed that under the new tariff regime, customers on Band A Feeders who typically receive a minimum supply of power for 20hours per day, would now be obliged to pay N225/kwh.

“According to the Order, this new tariff is modeled to cushion the effects of recent shifts in key economic indices such as inflation rates, foreign exchange rates, gas prices, as well as enable improved delivery of other responsibilities across the value chain which impact operational efficiencies and ability to reliably supply power to esteemed customers.

“PHED assures Band A customers of full compliance with the objectives of the new tariff order”, he stated.

Ilvebare also said the management team was committed to delivering of optimal and quality services in this cost reflective dispensation.

The PHED further informed its esteemed customers on the other service Bands of B, C D & E, that their tariff remains unchanged, adding that the recently implemented supplementary order was only APPLICABLE to customers on Band A Feeders.

Oil & Energy

Renewable Energy Boom With Waste Problem

As the global renewable energy capacity increases, so does the amount of waste from end-of-life equipment from solar, wind and other renewable energy activities. If we don’t address this problem soon, it could become a whole new threat to the environment and human health.

While a transition away from fossil fuels to alternative green energy sources is helping the world to reduce its greenhouse gas emissions and combat climate change, it is important to consider the implications that new energy activities may have on the environment.

Solar panels and wind turbines have a limited lifespan and need to be disposed of appropriately once they reach this point. While some components can be recycled and reused, much of the old equipment ends up in landfills due to the lack of infrastructure in place to manage the materials suitably.

Renewable energy equipment, such as solar panels, contains components that can be harmful to humans, such as lead and cadmium, as well as other materials, like glass, aluminum, and silicon, which can be harmful to the environment if disposed of improperly.

One way that out-of-use equipment can be managed is through the creation of standards, such as the Waste Electrical and Electronic Equipment (WEEE) directive from the European Union, which provides guidelines for the gathering, handling, recycling, and recovery of solar panels.

The U.S. Resource Conservation and Recovery Act (RCRA) also addresses the correct disposal of solar panels.

However, many countries have yet to introduce clear standards for renewable energy equipment disposal, which has led to dangerous methods of disposal.

Several countries around the globe are rapidly increasing their solar and wind energy capacity, which relies on the production and installation of millions of solar panels and turbines. Tens of millions of solar panels are being installed each year in the U.S. alone, and globally the figure is over a hundred million.

Despite the accelerated pace of the rollout, there are few recycling facilities prepared to manage old equipment.

Some countries are managing equipment disposal better than others. For example, France claims that 90 percent recycling efficiency is achieved in some of its flagship disposal facilities.

However, others do not have mechanisms in place to even consider recycling old equipment. While it is important to put proper waste disposal mechanisms in place for the safety of people and the environment, it can also be a lucrative business.

According to a study by the International Renewable Energy Agency (IRENA) and the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), the cumulative value of materials that can be recycled from solar photovoltaic (PV) waste is estimated at $4 billion by 2040 and $8.8. billion by 2050.

Supplies of many of the materials used to produce green energy equipment are finite, meaning it is important to recycle materials to reproduce equipment to continue to produce renewable energy. Jinlei Feng, a programme officer at IRENA, explained, “By 2050, there will be more than 210 million tonnes of cumulative solar PV waste globally and more than three-quarters of that waste will be generated after 2040 and 40% in the last five years between 2045-2050”.

Feng added, “Annual solar PV waste generation will touch 10 million tonnes by 2040 and increase to 20 million tonnes by 2050”.

India is currently trying to navigate solar waste problem. Pavagada in the south of India is home to the world’s third-largest solar power plant, which holds 25 million panels across a 50 km2 park, with a capacity of 2,050MW. There are 11 other giant solar parks across the country, with plans to develop a further 39 across 12 states by 2026.

However, with great solar ambitions comes significant waste. India is aiming for a solar output capacity of 280GW by 2030, of which 70.1GW is already installed.

One study predicts that this will produce an accumulation of over 600,000 tonnes of solar waste by the end of the decade, which could increase 32-fold to over 19 million tonnes by 2050.

Although there are protocols in place to manage the disposal of old equipment, which state that solar waste from the plants must be transferred to e-waste contractors, authorized by the Central Pollution Control Board (CPCB), within a specified timeframe – typically 90 or 180 days – few abide by these rules.

Most solar farms are in remote areas and must pay to transport old equipment to authorised contractors. Solar glass has no real value, meaning there is little incentive for waste contractors to collect and manage the equipment.

This has led to the development of a network of informal operators – who dismantle, aggregate, transport and recycle panels.

Instead of ensuring proper disposal methods are followed, many operators sell their waste equipment to informal buyers, meaning the materials cannot be recycled and repurposed, and many of the materials end up harming both people and the environment.

To ensure that renewable energy equipment is disposed of appropriately, and recycled where possible, governments must establish clear standards and regulations for energy waste disposal.

Further, they must ensure the mechanisms are in place and funding is available to guarantee proper disposal takes place. Without the necessary standards, green energy equipment could contribute to environmental and health problems in the coming decades.

Bradstock writes for Oilprice.com.

By: Felicity Bradstock

-

Rivers5 days ago

Rivers5 days agoPolice Arrest Vigilante Commander, Others Over Robbery In Rivers

-

Education5 days ago

Education5 days agoFormer VC Advocates Drug Test For University Lecturers

-

News12 hours ago

Reps Order NERC To Suspend Implementation Of New Electricity Tariff

-

News5 days ago

News5 days agoSpeak Truth To Power, Prof Omotola Tells Journalists

-

Politics5 days ago

Politics5 days agoBayelsa Repositioning Local Councils For Service Delivery – D’Gov

-

Niger Delta12 hours ago

Calabar Port Dormant In 25 years -Manager

-

Nation5 days ago

Nation5 days agoWIW: Banigo Advocates Legislative Impetus

-

News5 days ago

News5 days agoLet’s Fight To Save Rivers’ Soul Together