Business

Solids Control Equipment and Services ¨C KOSUN

Solids control, or solids control equipment by Kosun – top solids and liquid separation service provider and stage 3-5 precision solids control system manufacturer in China, serving clients around the world for 25 years.

Solids Control Equipment-KOSUN

-DC Series Decanter Centrifuge: is used to separate suspended solids ¡Ý2¦Ìm in diameter and treat the drilling mud and fluids. It is especially effective when used in oilfield service industry, industrial service industry and especially in environmentally sensitive areas. This type of centrifuge is high in recovery rate, effective in solids control and remarkable in the reduction of cost spent on drilling mud resupplying and management. It is a very sophisticated dynamic balancing machine, able to operate stably with the whirling speed ranging from 0 to 3900 and generate centrifugal force of 3000G.

-D Series Decanter Centrifuge: is used in separating suspension of solids phase with particle ¡Ý2¦Ìm in diameter, and can be used at Environmental Protection Industry, Chemical Industry, Food Industry, Pharmaceutical Industry,and many other related industries, and can the replacement of GEA westfalia centrifuges or Alfa Laval centrifuge.

-Desander: In the 2nd stage of solids control for drilling fluids, desander makes separations between 45 and 75 ¦Ìm.

-Desilter: In the 3rd stage of solids control for drilling mud, the Desilter by Kosun makes separations between 15 and 45 ¦Ìm.

-Diesel tank: is the specialized tank used to provide and store fuel for diesel engine and generator, which mainly consists of storage tank, self-priming centrifugal oil pump, filter, flowmeter, explosion-proof liquid-level switch, liquid level gauge, elevated oil tank & manifold and stainless steel valve.

-Shear Pump: For a quick concoction of high-performance mud, and shorten the time spent on it, so as the and wells’ economic benefits increased, the shear pump by Kosun is performing good.

-Screw Pump: is used to feed drilling fluids to decanter centrifuge since drilling fluids is pushed to proceed along axial direction evenly.

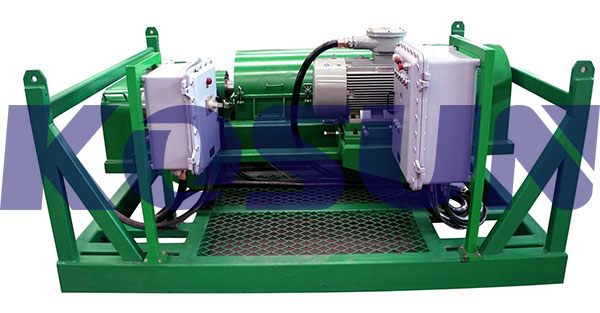

-Mud Agitator: is used to agitate and mix the drilling mud to prevent solids particles from depositing in the circulating tank and to stabilize the performance of drilling fluids.

-Mud Gun: is for jets drilling fluids with high pressure inside mud tanks.

-Balanced Elliptical Motion Shaker: In drilling top-hole sections where heavy, high-volume solids, it canremove viscous solids and eliminate larger particles in drilling fluids.

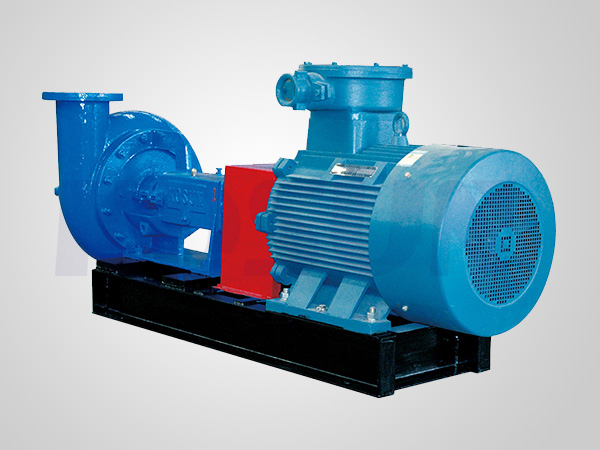

-Centrifugal Pump: can be used as feeding pump for desander, desilter, or as mixing pump for jet mud mixer.

-Jet Mud Mixer: is mainly applicated in concoct the drilling fluids and to change its density and viscosity.

-Water tank: can be widely used in petrochemical industry, food industry and industrial water.

-Submersible Slurry Pump: is used to pumping of thick oil, oil residue, dirty oil, mud, mortar, running sand and other liquids from the municipal sewerage, so its application industry can be related with many, such as environmental protection, new type building materials, coal washing, municipal projects, thermal power generation, coal gas coking plant, refinery, steel mills, mining, paper making, cement plant or food producting factory.

-Linear Motion Shale Shaker: The shale shaker is the first stage of solids control equipment in drilling purification system. It can remove cuttings above 75 ¦Ìm brought from the drilling well to leave the liquid with smaller particles into the tanks below, which will flow into next grade solids control equipment for further treatment.

-Drilling Fluid Tank: is often rectangle with its base constructed by H-shape steel as the main frame and other building materials, made to be skid mounted after satisfying the strength requirement.

-Hi G dryer: is used to recover cuttings from water-based or oil-based drilling fluids so as to lower the hydraulic proportion than 10% and significantly reduce the cost on waste discharge. It is proved to be particularly effective in recovering the oil-based mud cuttings.

-Drilling Mud Cleaner: Combing desander and desilter, the Drilling mud cleaner by Kosun can be the mud cleaner miswaco replacement now, and good quality mud cleaner is for sale now.In the second or third stage separation equipment for drilling fluids, Drilling fluids mud cleaner by Kosun deals with the mud being treated by the first grade separation equipment.

Solids Control Services ¨C KOSUN

KOSUN products are typically applied to the following three fields:

(1) Petrochemical field: petroleum solids control equipment and system, zero discharge of drilling mud, and upstream & downstream products of petrochemical industry;

(2) Environmental protection field: centrifuge environmental industry, tailing treatment/ore classification, soil ecological restoration, chemical/parmaceutical/food processing, etc.;

(3)Infrastructure field: HDD, metro tunnel shield construction, pipe gallery laying, diaphragm wall, pile foundation slurry, riverway and lake dredging, etc.

Founded in 1992, Xi¡¯an KOSUN Machinery Co., Ltd. is a state-level high-tech enterprise integrating environmental products R&D, production and sales, general project contracting and environmental management services. KOSUN is committed to the quality policy of ¡°Good Faith, Quality Goods and Transcendence¡± and is based on the Chinese market to provide worldwide users with all kinds of professional solid-liquid separation products and comprehensive treatment services. (Editor:Kosun Lily.Wang)

by Okwum Uchekcukwu